Effective and efficient value creation is crucial – but simple optimization in silos along functions is no longer sufficient. Companies must combine efficiency, resilience and sustainability. The solution is holistic end-to-end value creation planning, combined with a forward-looking, integrated digital infrastructure.

In the current era of slowing growth, the focus is shifting from generating revenue to improving the bottom line by increasing efficiency. In doing so, however, companies can no longer optimize in silos and look at areas such as purchasing and production individually as they used to. Recent disruptions have shown how fragile supply chains are and how fragile the network of value creation within the company is as a result. Interdependencies between divisions can quickly lead to disruptions.

On the one hand, there is EBIT, efficiency and cost pressure, while on the other hand, the need to invest in flexibility and resilience remains. Added to this is the challenge of acting sustainably. Developing more sustainable products, eco-friendly transportation, and reducing the carbon footprint of production – all have implications for value chains and financial resources.

An end-to-end approach to the value chain

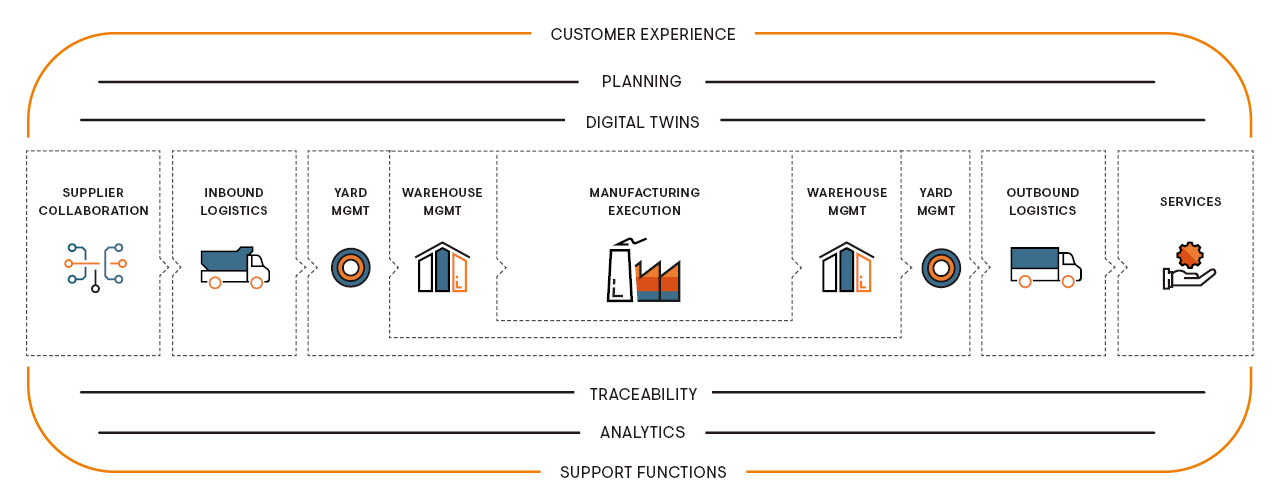

As part of the SAP transformation, companies are rethinking their existing operating model and searching for a robust governance model – because the momentum to address business processes and the value chain is ideal. The focus is no longer solely on cost reduction, but above all on building planning-oriented processes in the interplay of a wide variety of operational processes. The solution to the requirements of efficiency, resilience and sustainability is holistic planning of the value chain using an end-to-end approach. This end-to-end thinking extends to both a vertical and horizontal dimension. On a horizontal level, the entire value chain – design-to-operate – is considered from its beginning to its end, through capabilities such as planning, manufacturing and logistics. Vertically, this means thinking from the formulation of a strategy to its concrete implementation – whether at the technical level or in practical adjustments at the operational shop-floor level.

Complex supply chains require targeted control and transparent and flexible data analysis. The classic flow of goods and the flow of value are therefore joined by the view of a third stream moving along the value chain: integrated information and data. Innovative tools play a role here, such as planning algorithms and AI systems that help manage the interconnections in the networks. There is significant added value hidden in the flow of data and information – but it requires digitization and the development of future-proof IT and software architectures, and that too from an end-to-end perspective.

360° Value Chain Assessment

Full end-to-end control and transparency over the value chain is not achieved overnight, and not in a single leap. The starting point for our customers is often a 360° Value Chain Assessment. Depending on the needs, the Value Chain Assessment can cover the entire supply chain, from planning to delivery, or be conducted in smaller increments. We analyze the current maturity level of the company in relation to the supply chain – both in terms of capabilities and business processes. Based on this, we derive with our customers which maturity level the company would like to achieve in perspective via process, organization and technology along with the strategy and target operating model. We identify which future capabilities are needed and how they can be achieved through process changes, organizational transformation and digitization. The result of such an assessment is a target picture developed in collaboration with the customer and a roadmap for its implementation.

Integrated Business Planning

Often, there is a need for action in the planning environment. Many companies have focused a large part of their attention on increasing production efficiency and operational execution, while the maturity level of integrated planning remains comparatively low. In such situations, it is advisable to link the relevant levels and players in the planning process (sales, finance, supply chain, manufacturing, etc.) as part of Integrated Business Planning to enable holistic business planning.

Our Fast Value approach to Integrated Business Planning offers rapid added value here. Instead of complex solutions that are supposed to catapult the company forward in one giant leap, it is sensible to further develop processes, organization and systems iteratively by means of a minimum viable product (MVP), always with the goal of creating added value early on while keeping risk and stress level low. In the same way, the Fast Value approach also helps to establish new business models thanks to high development speed and agility.

How can we help you transform your value chain? Our “Power of Three”, consisting of cbs and its subsidiaries leogistics and Trebing + Himstedt, approaches your challenges with passion. We combine expertise and capacity in diverse topics such as Integrated Business Planning, Manufacturing and Logistics – from strategy to implementation on the store floor or loading dock.

Your Contact